In the vibrant world of custom apparel creation, Direct to Film (DTF) transfers have emerged as a revolutionary technique, bringing a seamless blend of innovation and artistic expression. This blog peels back the curtain to unveil the intricate process of how DTF transfers, specifically tailored for T-shirts, are expertly produced. Join us on this journey behind the scenes and discover how DTF transforms your design visions into wearable art.

Understanding DTF Transfers for T-Shirt Marvels: The Perfect Fusion of Digital and Fabric Realms

DTF transfers for T-shirts embody a modern approach to apparel customization, allowing for direct application of digital designs onto fabric. This process bypasses traditional methods, enabling unparalleled precision and vibrancy. Let’s explore the fascinating steps that make DTF transfers the go-to choice for crafting T-shirt masterpieces.

The Production Process Unveiled: From Digital Concepts to Wearable Art

-

Digital Artistry: The journey commences with the creation of digital designs, where artists bring their concepts to life on a virtual canvas. This step is crucial in setting the stage for the transformation from a digital masterpiece to a tangible, wearable T-shirt design.

-

DTF Printing Precision: State-of-the-art DTF printers take center stage, transferring the digital design onto a special film with unmatched accuracy. This film serves as the conduit between the digital realm and the fabric canvas, capturing every detail with finesse.

-

Fabric and Garment Selection: Choosing the right fabric and garment is akin to selecting the perfect canvas for a painting. DTF transfers seamlessly adapt to various materials, from cotton to polyester blends, ensuring your T-shirt becomes the ideal medium for showcasing your personalized design.

-

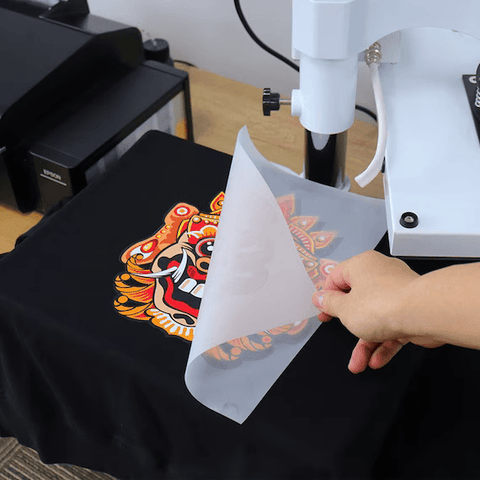

Heat Press Magic: The magic happens with the application of heat and pressure. Using a heat press, the DTF transfer film is pressed onto the fabric, resulting in a vibrant, high-quality print that seamlessly integrates with the T-shirt. This step ensures durability and longevity, even after multiple wears and washes.

-

Quality Assurance: Rigorous quality checks are implemented to guarantee that every T-shirt leaving the production line meets the highest standards. This includes scrutinizing details, colors, and overall print integrity to deliver a product that exceeds expectations.

-

Express Your Style: Once the T-shirt undergoes the DTF transfer process, it becomes a canvas for personal expression. Whether it's a unique design, a personalized message, or vibrant artwork, DTF transfers empower individuals to showcase their style with a wearable twist.

Conclusion: Elevating T-Shirt Customization to Artistic Heights

DTF transfers redefine the landscape of T-shirt customization, elevating it to new artistic heights. This behind-the-scenes glimpse into the production process showcases how DTF seamlessly integrates digital artistry with fabric, resulting in T-shirt marvels that are not just clothing but expressions of individuality. Embark on your personalized T-shirt journey with DTF transfers, where every design becomes a masterpiece.

Explore more about DTF transfers for T-shirts and kickstart your creative journey at NextDayDTF.

Comments (0)

There are no comments for this article. Be the first one to leave a message!