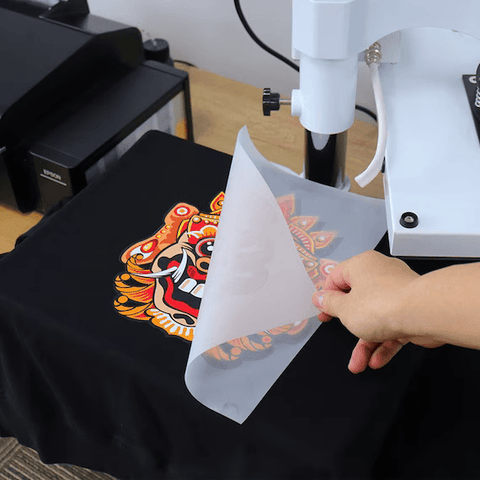

In the dynamic world of printing technology, Direct To Film (DTF) has emerged as a groundbreaking method that offers high-quality, vibrant prints on a variety of surfaces. To achieve optimal results with DTF, selecting the right heat press is crucial. In this guide, we'll walk you through the key factors to consider when choosing a heat press for DTF printing, ensuring that you make an informed decision to elevate your printing business.

1. Temperature Control Precision:

The first and foremost consideration when choosing a heat press for DTF printing is temperature control precision. DTF requires specific temperature settings for optimal adhesion and vibrant color transfer. Look for a heat press with accurate digital temperature controls and even heat distribution across the entire platen.

2. Pressure Consistency:

Consistent pressure is paramount for successful DTF printing. A heat press with adjustable pressure settings and even distribution ensures that the film adheres uniformly to the substrate, preventing uneven prints or incomplete transfers.

3. Size Matters:

The size of your heat press is directly related to the size of prints you intend to produce. Evaluate your business requirements and choose a heat press that accommodates the dimensions of your typical DTF prints. Remember that having a larger platen allows for versatility in handling various substrates.

4. Versatility in Substrates:

DTF printing caters to a wide range of substrates, from fabrics to hard surfaces. Select a heat press that offers versatility in handling different materials. This adaptability will enable you to explore diverse printing opportunities and meet the demands of a varied clientele.

5. User-Friendly Interface:

A user-friendly interface can significantly enhance your DTF printing experience. Look for a heat press with an intuitive control panel that allows you to easily adjust settings, saving you time and minimizing the learning curve for new operators.

6. Durability and Build Quality:

Investing in a durable heat press is a smart long-term strategy. Consider the build quality, materials used, and the reputation of the manufacturer. A robust heat press not only ensures consistent performance but also minimizes the need for frequent maintenance and repairs.

7. Budget Considerations:

While it's tempting to opt for the most feature-rich heat press, it's essential to align your choice with your budget. Evaluate the features that are crucial for your DTF printing needs and find a balance between affordability and functionality.

8. Customer Reviews and Recommendations:

Research and read customer reviews to gain insights into the real-world performance of the heat press models you are considering. Seek recommendations from industry peers who have experience with DTF printing to make an informed decision.

Choosing the right heat press for DTF printing is a pivotal step towards achieving exceptional results in your printing business. By prioritizing factors like temperature control precision, pressure consistency, size, versatility, user-friendliness, durability, and budget considerations, you can ensure that your heat press aligns seamlessly with the requirements of DTF printing. Elevate your printing game and unlock new possibilities with the perfect heat press for your DTF endeavors.

Comments (0)

There are no comments for this article. Be the first one to leave a message!