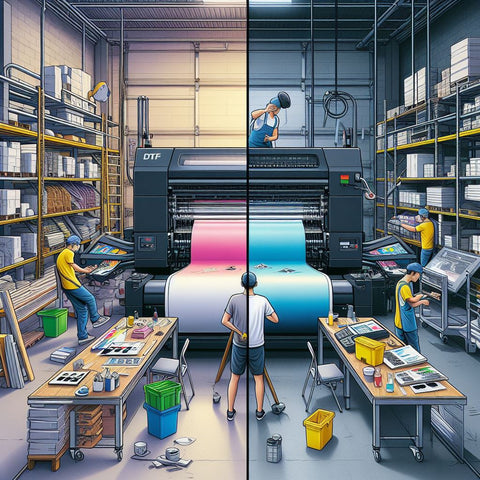

Different Application Techniques for DTF Transfers

DTF transfers, also known as direct to film transfers, have revolutionized the world of custom t-shirts. This innovative printing technique offers vibrant and durable prints that are perfect for creating unique and long-lasting designs. If you're new to DTF printing or looking to expand your skills, this article will explore different application techniques that you can use to achieve the best results for your custom t-shirts.

1. Preparing Your Design

Before diving into the application process, it's essential to prepare your design properly. Make sure your design is in a vector format, such as SVG or AI, to ensure clarity and crispness. Additionally, ensure that the design is scaled to the desired size for printing on the t-shirt. Remember to consider the color scheme and the fabric you'll be printing on to ensure that your design pops.

2. Choosing the Right DTF Transfer Film

One crucial factor in achieving high-quality DTF prints is selecting the right transfer film. Different transfer films have varying properties, such as stretchability, opacity, and washability. Consider the fabric type and the intricacy of your design while choosing the transfer film. Conducting some test prints with different film options can help you determine the best fit for your requirements.

3. Heat Press Application

The most common method for applying DTF transfers to custom t-shirts is using a heat press machine. This technique ensures even heat distribution and consistent pressure, leading to excellent print quality. Place the polyester adhesive side of the transfer film onto the desired area of your t-shirt, cover it with a protective sheet, and press it with the recommended temperature and time settings. Remember to peel off the transfer film carefully while it's still warm.

4. Printing on Dark Fabrics

Printing on dark fabrics requires an additional step for achieving vibrant and visible DTF prints. After applying the transfer film using a heat press, peel off the protective sheet while the transfer is still warm. Then, cover the printed design with a layer of white primer using a screen or squeegee. The white primer will enhance the colors and prevent any underlying fabric color from affecting the final result.

5. Curing the DTF Prints

To ensure the longevity of your DTF prints, proper curing is vital. After the transfer film is applied and peeled off, place the printed t-shirt onto a heat press machine again. Apply heat and pressure for the recommended duration to cure the prints. Curing ensures that the colors bond well with the fabric, creating a durable and wash-resistant design.

6. DTF Printing on Textured Fabrics

Printing on textured fabrics can pose a challenge due to the uneven surface. To achieve seamless prints on textured fabrics, consider using a sticky pad or cover sheet along with the heat press. This allows the transfer film to mold to the fabric's texture, resulting in a smooth and professional-looking print.

7. Hand Iron Application

While heat press machines offer precise temperature control and pressure, you can also apply DTF transfers using a household hand iron. This method is suitable for small-scale printing projects or when a heat press machine is not available. Set the iron to the recommended temperature, place the transfer film onto the t-shirt, and press firmly with even pressure. However, keep in mind that hand iron application might not provide the same level of consistency as a heat press.

8. Solvent Blotting Technique

The solvent blotting technique involves using a small amount of solvent, such as isopropyl alcohol, to blend and smooth the colors of your DTF prints. After applying the transfer film and peeling it off, lightly dampen a cloth or sponge with the solvent and gently blot the surface of the print. This technique helps remove any remnants of adhesive and enhances the vibrancy of the colors.

9. Combining DTF and DTG Printing

For truly unique and eye-catching designs, consider combining DTF and DTG printing techniques. DTG printing can add intricate details and gradients to your design, while DTF transfers provide a vibrant base. Start by printing the base layer using the DTF technique and then use a DTG printer to add detailed elements on top. This combination allows you to achieve the best of both worlds and create visually stunning custom t-shirts.

10. Post-Printing Care

Proper care and handling can significantly impact the longevity of your DTF prints. Always follow the garment care instructions provided by the manufacturer. Turn the printed t-shirts inside out before washing to protect the print. Wash them using a gentle cycle and cold water to prevent color fading. Avoid using harsh detergents or bleaching agents. Lastly, tumble dry at a low temperature or air dry to preserve the print quality.

11. Marketing Your DTF Prints

Now that you have mastered various DTF application techniques, it's time to focus on marketing your custom t-shirts. Use social media platforms to showcase your designs and engage with potential customers. Create visually appealing images of your DTF prints on different t-shirts and showcase them on your Shopify store. Implement SEO strategies, such as using relevant keywords like "DTF transfers," "DTF prints," and "custom t-shirts," in your product descriptions, titles, and meta tags, to drive organic traffic to your store.

12. Embrace Creativity and Experimentation

When it comes to DTF transfers, the only limit is your creativity. Don't be afraid to experiment with different designs, color combinations, and application techniques. Stay updated with the latest trends in the custom t-shirt industry and incorporate them into your prints. Keep refining your skills and exploring new possibilities to create unique and extraordinary custom t-shirts that will enthrall your customers.

In a World of Custom T-Shirts, DTF Transfers Reign Supreme

DTF transfers have emerged as a game-changer in the custom t-shirt industry. With their vibrant colors, durability, and versatility, DTF prints offer endless possibilities for designers and entrepreneurs. By following the different application techniques discussed in this article, you can ensure that your DTF prints stand out from the competition. Remember to choose the right transfer film, master heat press application, and explore innovative methods like solvent blotting and combining with DTG printing. With proper care and effective marketing efforts, your DTF prints can become a driving force behind the success of your Shopify store.

Comments (0)

There are no comments for this article. Be the first one to leave a message!